Introduction

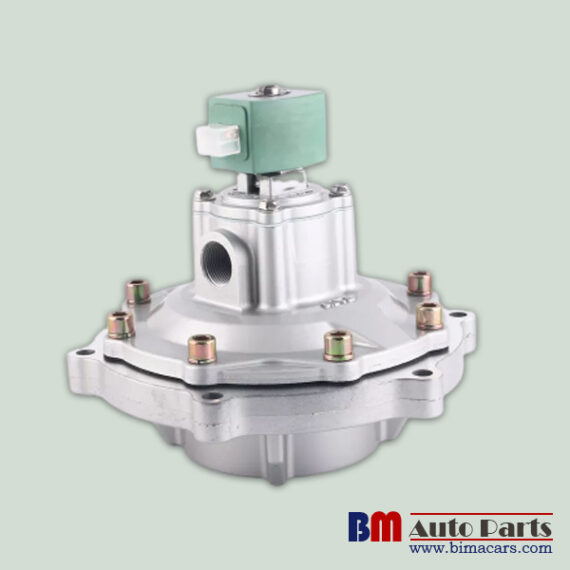

ASCO pulse valves are crucial components in various pneumatic systems, employed for their precise control of airflow and efficient operation. Proper maintenance of these valves is paramount to ensure their longevity, reliability, and optimal performance. This article delves into the technical aspects of ASCO pulse valve maintenance, offering insights into the maintenance process, common issues, and best practices.

Maintenance Process

Maintenance of ASCO pulse valves involves a systematic approach to ensure all components are inspected, cleaned, and replaced if necessary. The process typically includes the following steps:

- Shutdown and Isolation: Before beginning maintenance, it’s essential to shut down the system and isolate the valve from the air supply.

- Disassembly: Carefully disassemble the valve, noting the sequence and position of each component. This ensures correct reassembly.

- Inspection: Thoroughly examine each component for wear, damage, or signs of deterioration. Focus on diaphragms, seals, gaskets, and solenoids.

- Cleaning: Clean components using appropriate cleaning agents that won’t compromise the integrity of the valve materials.

- Replacement: Replace worn or damaged components with genuine ASCO replacement parts to maintain original performance standards.

- Reassembly: Reassemble the valve in the correct sequence, ensuring proper alignment and snug fastening of components.

- Testing: Test the valve’s operation after reassembly to ensure it functions as expected.

Common Maintenance Issues

Understanding common issues encountered during ASCO pulse valve maintenance is crucial for effective troubleshooting. Some common issues include:

- Diaphragm Wear: Diaphragms may wear due to continuous pulsating action, leading to leaks and reduced valve efficiency.

- Solenoid Malfunction: Solenoids can deteriorate over time, affecting the valve’s responsiveness.

- Clogged Ports: Airborne contaminants or debris can block valve ports, affecting airflow and valve operation.

- Leaking Seals: Worn seals can lead to air leakage, reducing the valve’s efficiency and accuracy.

Best Practices

To ensure successful ASCO pulse valve maintenance, adhere to the following best practices:

- Regular Inspection: Schedule routine inspections to identify issues early and prevent major failures.

- Use Genuine Parts: Always use genuine ASCO replacement parts to maintain the valve’s original performance.

- Proper Cleaning: Use appropriate cleaning agents and techniques to avoid damaging valve materials.

- Documentation: Keep detailed records of maintenance schedules, replacement parts used, and any issues encountered.

- Training: Ensure maintenance personnel are adequately trained to handle ASCO pulse valves, promoting proper handling and upkeep.

Conclusion

Effective maintenance of ASCO pulse valves is crucial for maintaining the efficiency and reliability of pneumatic systems. By following a systematic maintenance process, addressing common issues, and implementing best practices, industries can ensure that ASCO pulse valves continue to deliver precise airflow control and optimal performance, contributing to the smooth operation of diverse applications.