Introduction

ASCO repair kits have long been recognized as a hallmark of precision engineering in the pneumatic industry. This article unveils the meticulous craft, diverse applications, and compatibility with an array of valve models that define ASCO’s repair kits as an essential component for industries seeking top-tier pneumatic performance.

Craftsmanship Unveiled: The Repair Process

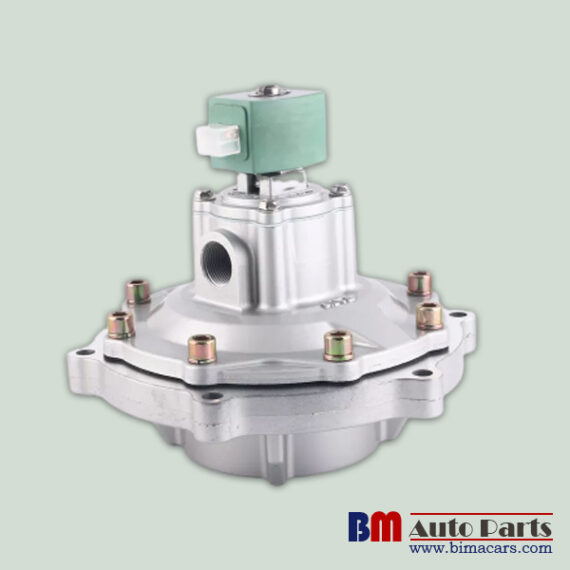

ASCO repair kits are a testament to precision craftsmanship. Every kit undergoes a meticulous manufacturing process that includes the careful assembly of components like diaphragms, springs, and gaskets. Engineers ensure an exact fit and function, effectively restoring valves to their peak operational condition. The use of top-tier materials guarantees resilience even in challenging operational environments, reflecting ASCO’s commitment to long-lasting quality.

Versatile Applications

ASCO repair kits are highly versatile and find applications across an extensive range of industries where pneumatic systems are critical. These kits are indispensable in dust collection systems, facilitating efficient filter cleaning and maintaining operational efficiency. Pneumatic conveying systems, vital in industries spanning cement to food processing, also rely on ASCO repair kits for uninterrupted material transfer. Moreover, ASCO repair kits play a pivotal role in ensuring the reliability of gas and fluid control systems in sectors such as energy, manufacturing, and beyond.

Compatibility with a Multitude of Valve Models

A distinguishing feature of ASCO repair kits is their compatibility with a broad spectrum of ASCO valve models. Whether it’s the renowned series like the 2-way, 3-way, or 4-way valves, these kits integrate seamlessly, simplifying maintenance procedures for operators. This adaptability underscores ASCO’s dedication to offering comprehensive solutions that cater to diverse pneumatic system needs.

Conclusion

ASCO repair kits stand as a pinnacle of precision engineering in the pneumatic domain. Their rigorous manufacturing process, wide-ranging applications, and compatibility with an array of valve models render them indispensable for industries prioritizing efficiency and dependability. By restoring valves to their optimal state, ASCO repair kits play a pivotal role in streamlining operations, enhancing productivity, and contributing to the overall success of industries worldwide.